- Home

- /

- Techinical Info

- /

- Stainless Steel Pipe

Techinical Info

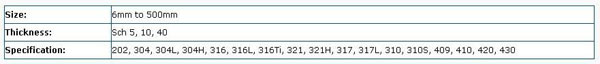

Stainless Steel Pipe

Seamless Pipes, Tubes –1/2” to 24” Welded Pipes, Tubes – 1/2” to 60”

ASME SA53 Grade B, API 5L Grade B

ASME SA106 Grade A, SA106 Grade B, SA106 Grade C, P265GH EN10216-2

ASME SA179, SA192, SA210 Grade A1, SA210 Grade C, BS3059 Grade 320, 360, 440

ASME SA-179, SA-192, SA210-A1, SA210-C, SA213, BS-3059 Gr.320, Gr.360, Gr.440

ASTM A500, ASTM A513, ASTM A787 Electric Resistance Welding Round, Square, Rectangular Tubing

ASTM A500 Grade B, ASTM A500 Grade C Structural Steel Tubes in Welded (ERW) & Seamless

ASTM A214 / A214M Electric-Resistance-Welded Carbon Steel Heat-Exchanger & Condenser Tubes

ASME SA213 Grade T11/T-11, T12/T-12, T22/T-22, T91/T-91, T92/T-92, T5/T-5, T9/T-9, T1/T-1

ASME SA249 Grade 304, 304L, 304H, 316, 316L, 316H, 316Ti, 317L, 321, 321H, 347, 347H

ASME SA269 Grade 304, 304L, 304H, 316, 316L, 316H, 316Ti, 317L, 321, 321H, 347, 347H

ASME SA213 Grade 304, 304L, 304H, 316, 316L, 316H, 316Ti, 317L, 321, 321H, 347, 347H

ASME SA312 TP304, 304L, 304H, 310S, 316, 316L, 316H, 316Ti, 321, 317L, 321H, 347, 347H

ASME SA333 Grade 1, 3, 4, 6, 7, 8, 9, 10, 11, P265NL EN10216-4 LTCS

ASME SA335 Grade P1, P2, P5, P7, P9, P11, P12, P22, P91, P92

ASME SA335 Grade P-1, P-2, P-5, P-7, P-9, P-11, P-12, P-22, P-91, P-92

API 5L X42, API 5L X46, API 5L X52, API 5L X56, API 5L X60, API 5L X65, API 5L X70,

API 5L X80, API 5L X100 LSAW PSL1, LSAW PSL2, DSAW PSL1, DSAW PSL2,

Submerged Arc Welded, U-O-E (UOE), J-C-O (JCO) Process, FBE, 3LPE, 3LPP Coated

API5LX-42, API5LX-46, API5LX-52, API5LX-56, API5LX-60, API5LX-65, API5LX-70

API5LX-80, API5LX-100 Longitudinal Submerged Arc Welded, High Frequency Welded

PSL 1 LSAW, PSL 2 LSAW, PSL 1 DSAW, PSL 2 DSAW, Submerged Arc Welded

API 5L Grade B LSAW, DSAW, HSAW, SPIRAL WELDED, ERW, HFW PSL1, PSL2

API 5L X-42 LSAW, DSAW, HSAW, SPIRAL WELDED, ERW, HFW PSL1, PSL2 (Sour Service)

API 5L X-46 LSAW, DSAW, HSAW, SPIRAL WELDED, ERW, HFW PSL1, PSL2 (Sour Service)

API 5L X-52 LSAW, DSAW, HSAW, SPIRAL WELDED, ERW, HFW PSL1, PSL2 (Sour Service)

API 5L X-60 LSAW, DSAW, HSAW, SPIRAL WELDED, ERW, HFW PSL1, PSL2 (Sour Service)

API 5L X-65 LSAW, DSAW, HSAW, SPIRAL WELDED, ERW, HFW PSL1, PSL2 (Sour Service)

API 5L X-70 LSAW, DSAW, HSAW, SPIRAL WELDED, ERW, HFW PSL1, PSL2 (Sour Service)

API 5L X-80 LSAW, DSAW, HSAW, SPIRAL WELDED, ERW, HFW PSL1, PSL2 (Sour Service)

API 5L X-100 LSAW, DSAW, HSAW, SPIRAL WELDED, ERW, HFW PSL1, PSL2 (Sour Service)

L245 (Grade B), L290 (Grade X42), L360 (Grade X52), L415 (Grade X60)

L450 (Grade X65), L485 (Grade X70), L555 (Grade X80) PSL-1, PSL-2

ASME SA 671 / ASTM A 671 / ASME SA 672 / ASTM A 672 ELECTRIC-FUSION- WELDED

SA671 Grade CA55, CB60, CB65, CB70, CC60, CC65, CC70, CD70, CD80

SA672 Grade A45, SA672 Grade A50, SA672 Grade A55

SA672 Grade B55, SA672 Grade B60, SA672 Grade B65, SA672 Grade B70

SA672 Grade C55, SA672 Grade C60, SA672 Grade C65, SA672 Grade C70

SA672 Grade D70, SA672 Grade D80

SA672 Grade L65, SA672 Grade L70, SA672 Grade L75

Honed Tubes, Skived and Roller Burnished Tubes H8/H9 Tolerance

Cold Drawn Precision Seamless Tubes / High Pressure Diesel Fuel Injection Tubing

DIN EN 10305-1 Seamless Grade E215, E235, E255, E355, E410 +C, +LC, +SR, +A, +N

DIN 2391 Grade ST35, ST35.4, ST35.8, ST37, ST37.4, ST37.5, ST42, ST42.2, ST45, ST45.8

DIN 2391 Grade ST44, ST44.4, ST52, ST52.0, ST52.3, ST52.4 GBK Annealed, NBK Normalized

DIN EN 10305-2 Welded Grade E215, E235, E255, E355, E410 +C, +LC, +SR, +A, +N

Cold Drawn Seamless High Tensile Hydraulic Tubes ST37.4 NBK DIN 2391C / DIN 2445

Cold Drawn Seamless High Tensile Hydraulic Tubes E235N EN 10305-4

Cold Drawn Seamless High Tensile Hydraulic Tubes ST52.4 NBK DIN 2391C / DIN 2445

Cold Drawn Seamless High Tensile Hydraulic Tubes E355N EN 10305-4

St.37-2 DIN17121, ST37-2 DIN 17121, S235JRH EN 10210-1, EN10210-2

St.52-3 DIN17121, ST52-3 DIN 17121, S355J2H EN 10210-1, EN10219-2

ST52-3 Seamless Pipes, Tubes ST 52-3 Seamless Hydraulic Pipes, Tubes

ST42-3 Seamless Pipes, Tubes ST 42-3 Seamless Hydraulic Pipes, Tubes

ST37-2 Seamless Pipes, Tubes ST 37-2 Seamless Hydraulic Pipes, Tubes

Hot Rolled Seamless Pipes for Cylinder Grade 34CrMo4

ST52.0 / ST37.0 DIN 1629 / DIN 2448 HFS - Hot Finished Seamless Mechanical Tubes

ST52.3 / ST52.3N DIN 17121 / DIN 2448 Hot Finished Seamless Tubes & Pipes

E355 / E355+AR DIN 10297-1 HFS - Hot Finished Seamless Tubes & Pipes

ST52 DIN 2391 Seamless Tubes for Hydraulic Cylinder

St 52.0 DIN 2391 Seamless Tubes for Hydraulic Cylinder

ST 52 DIN2391 PART 1 Grade A, B, C in Condition BK, BK+S, BKW, GBK, NBK

Cold Drawn High Precision Seamless Steel Tubes DIN2391/DIN1629/EN10305

St35(E235), St37.4, St45(E255), St52(E355) NBK(+N) GBK(+A) BK(+C) BKW(+LC) BKS(+SR)

DIN 1630 St37.4, St44.4, St52.4 JIS G3441, DIN-1630 ST 37.4, ST 44.4, ST 52.4

DIN 1629 St37.0, St44.0, St52.0 JIS G3444, DIN-1629 ST 37.0, ST 44.0, ST 52.0

DIN 2393 St44-2, St52-3 JIS G3445, DIN-2393 ST 44-2, ST 52-3 JIS-G-3445

DIN 2394 St44-2, St52-3 JIS G3445, DIN-2393 ST 44-2, ST 52-3 JIS-G-3454

DIN 17175 St35.8, St45.8, 17Mn4, 19Mn5, 15Mo3 JIS G3455, ST 35.8, ST 45.8

ASTM A161 T1 JIS G3460, ASTM A500 A, B, C, D BS 970, ASTM A519 BS 3059

Tubular Hot Finished Structural Seamless Hollow Sections EN 10210-1/2

Tubular Cold Forming Structural Welded ERW HFW Hollow Sections EN 10219-1/2

EN 10210-1/2 Grade S235JRH, S275JOH, S275J2H, S355JOH, S355J2H

EN 10210-1/2 Grade S355K2H, S420NH, S420NLH, S460NH, S460NLH

EN 10219-1/2 Grade S235JRH, S275JOH, S275J2H, S355JOH, S355J2H

EN 10219-1/2 Grade S355K2H, S420NH, S420NLH, S460NH, S460NLH

S355J2H DIN 2448 EN10210-1 Hot Finished Seamless Tubes

S355G15+N EN10225 Seamless Tubes, BS7191 355EM Seamless Tubes

S355J2H EN 10210 Seamless Hot Finished Structural CHS Circular Hollow Sections

S355J2H EN 10210 Seamless Hot Finished Structural SHS Square Hollow Sections

S355J2H EN 10210 Seamless Hot Finished Structural RHS Rectangular Hollow Sections

S355J2H EN 10219 Welded/ERW Cold Forming Structural CHS Circular Hollow Sections

S355J2H EN 10219 Welded/ERW Cold Forming Structural SHS Square Hollow Sections

S355J2H EN 10219 Welded/ERW Cold Forming Structural RHS Rectangular Hollow Sections

Hot Rolled Seamless Tubes for Cylinder Grade 34CrMo4

Hot Finished Seamless Pipes for Hydraulic Cylinder Grade 34CrMo4

Hot Finished Seamless Tubes for Hydraulic Cylinder Grade 34CrMo4

Hot Rolled Seamless Pipes for Cylinder Grade 42CrMo4

Hot Rolled Seamless Tubes for Cylinder Grade 42CrMo4

Hot Finished Seamless Pipes for Hydraulic Cylinder Grade 42CrMo4

Hot Finished Seamless Tubes for Hydraulic Cylinder Grade 42CrMo4

20MnV6 / 20MV6 / 20MnV EN14A Din 1.5217 EN 10208-2 / EN 10294-1

DIN 17121 Seamless Steel Heavy Wall Tubes Material 20MnV6 (MW 450)

ISO 2938 Seamless Steel Mechanical Tubes Material 20MnV6 (MW 450)

34CrMo4 EN 10216-1/2 Quenched & Tempered Seamless Tubes for High Pressure Gas Cylinders

ASTM A519 Grade 1008, 1010, 1018, 1020, 1025, 1026, 1040, 1045, 1050, 4130, 4140, 4150, 4340

AISI 4130 L80 according to API 5CT, 75K according to API 6A Quenched / Hardened & Tempered

SAE 4130 L80 according to API 5CT, 75K according to API 6A Quenched / Hardened & Tempered

AISI 4140 L80, P110 according to API 5CT, API 6A, NACE MR-0175 Quenched / Hardened & Tempered

SAE 4140 L80, P110 according to API 5CT, API 6A, NACE MR-0175 Quenched / Hardened & Tempered

AISI 446, SUS446, SAE51446, UNS S44600, SUS 446, AISI-446, Din 1.4762, SAE J405, SAE 51446

Duplex 2205, Duplex SAF2205, Duplex SAF 2205, UNS S31803/S32205, Din 1.4462 EN 10088-3

Duplex SAF2205 SANMAC, URANUS 45N, PREN>33, PREN>34, PREN>35, PREN>36

Super Duplex 2507, Super Duplex SAF2507, Super Duplex SAF 2507, Super Duplex UNS S32750

Super Duplex SAF2507 UNS S32750 DIN 1.4410 EN10088 URANUS 47N(+) PREN>41 A182-F53

Super Duplex UNS S32760 F55 ASTM A182 F-55 SA182 F55 DIN 1.4501 UNS 32760

Bundy Tubes Copper Coated for Condenser Refrigerator Low Carbon Steel ERW

Copper Coated Condenser ERW/Welded Tubes for Refrigerator ASTM A254-94

ERW Single Layer Copper Coated Bundy Tube/Pipe Low Carbon Steel

ERW Copper Brazed Bundy Tube for Wire Tube Condenser, Evaporators, Refrigeration

-

Quick Inquiry Form

Sheth Haji Sabu Siddhiq Bldg.,1st Khetwadi,

3rd Floor, Room No- 63, mumbai-400004.

Sheth Haji Sabu Siddhiq Bldg.,1st Khetwadi,

3rd Floor, Room No- 63, mumbai-400004.